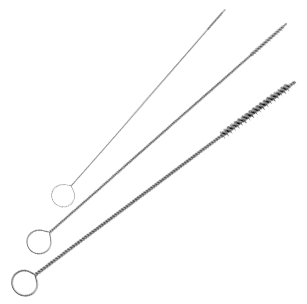

Tube Brushes

Manual Operation Tube Brushes

Power Driven, Cleaning and Deburring Tube Brushes

H1/H2 Holders for 1500 Series Brushes

1500 Power Driven Side Action Brushes of Steel or Stainless Steel

1600 Power Driven Carbon or Stainless Steel Tube Brushes

1700 Power Driven Silicon Carbide Filled Nylon Tube Brushes

1900 Rifle Brushes/Gun Brushes in Bronze/SS

2000 Power Driven Deburring or Polishing Brushes

A tube brush (also known as a pipe cleaning brush, spiral brush, or deburring brush) is designed for cleaning the inside of a cylinder. Our bristle and nylon tube brushes are perfect for low abrasion jobs, like removing dust and other debris from precision electronics or glass test tubes, while our metal tube brushes are designed for tough slag removal, as well as other cleaning, deburring, honing, and edging jobs in cylinders, pipes, and blind holes. If the brushes are used in environments where corrosion cannot be tolerated but stiffness is still required, use stainless steel tube brushes. If less abrasive action is required, use brass tube brushes. We stock manual operation brushes and power-driven deburring brushes in a range of diameters and a variety of materials including nylon, carbon steel, stainless steel, and brass. All our tube brushes are in stock and ready for immediate shipment.

What is a tube brush?

A tube brush (also known as a pipe cleaning brush, bottle brush, spiral brush, or deburring brush) is designed for cleaning the inside of tubes, cylinders, and other narrow openings. Tube brushes are commonly used to remove dirt, rust, residue, or burrs from metal, plastic, or glass tubing.

How do I choose the right tube brush for my application?

Solo Horton offers tube brushes in a variety of materials including nylon, carbon steel, stainless steel, and brass.

- Nylon tube brushes are gentle and ideal for cleaning sensitive surfaces like glass test tubes, electronics, and other precision instruments.

- Metal tube brushes (carbon steel, stainless steel, and brass) are designed for tougher jobs such as deburring, honing, and slag removal in pipes and cylinders. Choose stainless steel tube brushes for abrasive cleaning and in wet applications or brass tube brushes for softer metals like copper.

What sizes and diameters are available for tube brushes?

Solo Horton stocks manual operation tube brushes in diameters from .020” to 2” and overall lengths of 2 ¼” to 16 ½”. Power-driven tube brushes are available from ¼” to 2” in diameter and overall 3 9/32” to 6” long, giving you plenty of options for different applications.

Can tube brushes be used with power tools?

Yes—power-driven tube brushes from Solo Horton are specifically designed for use with power tools such as drills, drill presses, or die grinders. Each brush features a sturdy stainless-steel stem for secure attachment and durable bristles that withstand high rotational speeds.

Which industries use tube brushes?

Tube brushes are used in many industries where precision cleaning or deburring is required, including:

- Manufacturing and metalworking

- Automotive and aerospace

- Oil, gas, and energy

- Pharmaceutical and chemical processing

- Food and beverage productions

- Medical and laboratory equipment cleaning

- HVAC and plumbing maintenance

How do I order a custom size or material for a tube brush?

Solo Horton can custom-design tube brushes to your specifications. Contact us with your application details (tube size, material, cleaning requirements) and our team will build a custom brush to match your needs.

Are your tube brushes in stock and ready to ship?

Yes. All standard tube brushes are stocked and ready for immediate shipment, ensuring fast delivery for your cleaning or deburring projects.

What is the difference between a tube brush and a bottle brush?

Technically a bottle brush is a type of tube brush. While tube brushes and bottle brushes look similar, they’re made for different jobs. Tube brushes are long and narrow with dense bristles designed for tight, cylindrical spaces, while bottle brushes are wider and more flexible for cleaning larger openings in bottles or jars without scratching. Our 1200 and 1300 series work well as bottle brushes.

What are the typical applications for deburring tube brushes?

Deburring tube brushes are used to remove sharp edges, burrs, or leftover material from holes, tubes, and machined parts after manufacturing. Common applications include:

- CNC machining and metal fabrication, to smooth drilled or threaded holes.

- Medical device manufacturing, to clean internal passages and ensure burr-free surfaces.

- Precision manufacturing, where smooth edges are critical to part performance.

Questions & Answers

Not finding a product for your specific application?

Please call us to discuss your project.